SPIDER - Pump Control

SPIDER – Pump Control can operate several pumps with alternating operation – using only one level switch connection

A Universal Pump Control

Overall, SPIDER is a universal control, with many applications. On the same level switch, a high level or defective pump function can also be alerted.

This pump control can also be connected to a standard pressure transmitter or other level meter with 4-20mA signal with optional measuring range. With analog level signal connected, SPIDER can perform a valid pump flow calculation that has not been seen before, and based on this function, the need for pump service can be predicted.

Communication with SPIDER - Pump control

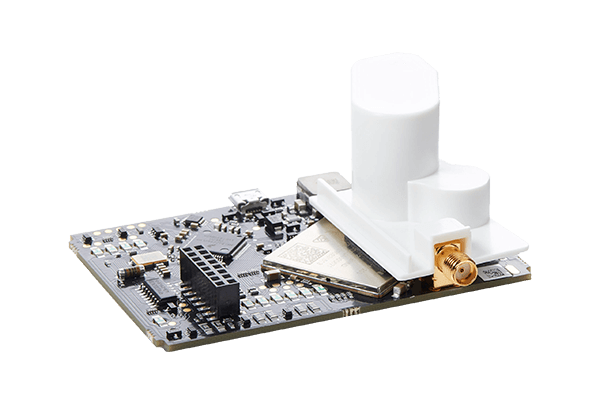

SPIDER boasts seamless communication using LTE-m (2G or 4G) modems, ensuring robust connectivity. Its communication module is engineered for effortless replacement, enabling seamless adaptation to future IoT requirements.

With the implementation of ModBus TCP/IP protocol, SPIDER offers encrypted TLS communication, guaranteeing top-notch security standards. All SPIDER registers share the same data type, simplifying data transmission with just one telegram update.

Versatility is SPIDER’s strength! It serves as a standalone unit for direct communication or effortlessly integrates with Acowa hiVe. This enables compatibility with a wide array of other protocol types, including REST API, granting limitless possibilities for your IoT ecosystem.

Interface and visualization options

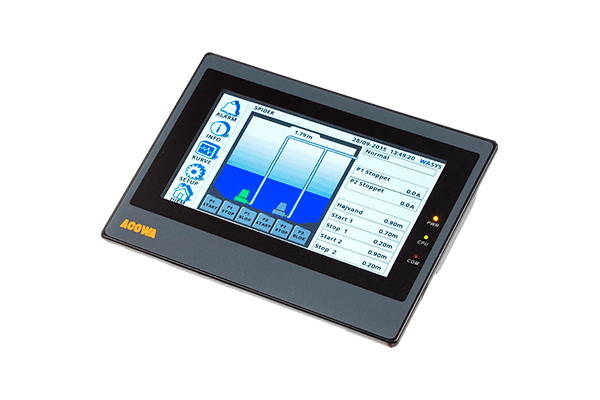

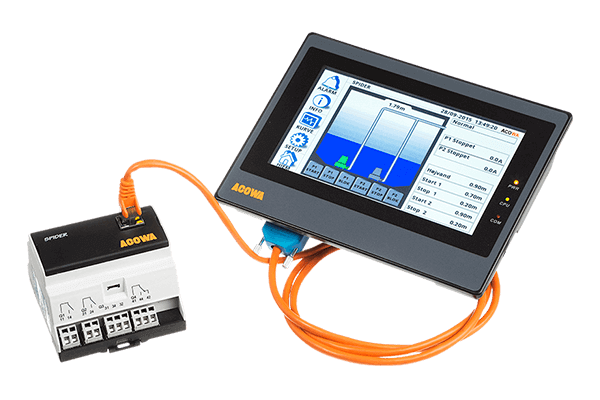

SPIDER offers multiple choices for user interface and data visualization. It features a convenient 2.4″ OLED display that seamlessly attaches to the device. Alternatively, you can opt for the EAGLE HMI 7″ graphic color touch display for a more interactive experience.

Besides its display screen, SPIDER provides the flexibility of using AcowaZoo, a free configuration tool, for easy control and visualization. Alternatively, you can leverage AcowaDash for additional functionalities.

Data Collection with external equipment

SPIDER excels at collecting data and logging signals from diverse sources, utilizing external standard 4-20mA / 0-10V DC or standard DI equipment.

On top of that, with the RS485 protocol, SPIDER effortlessly communicates with an array of external equipment, such as I/O modules, EAGLE HMI 7″ graphic color touch displays, frequency converters, flow meters, energy meters, and residual current circuit breakers.

Read more about the SPIDER - Pump control

Last but not least, for more info about SPIDER in a country near you, go to our agents page and connect to: Agents page/spider

Additionally, for danish speaking people – feel free to visit wasys.dk/spider/

Unique features of SPIDER - Pump control

- SPIDER can perform validated flow calculation. Likewise, it calculates the pumps’ “true” capacity, even for parallel operation. Based on this function, it can predict the need for pump service due to reduced capacity

- This device also provides the user with an inlet flow calculation showing the inlet profile to the pumping station

- It has the function for stormflow calculation, daily exercise, daily depth pumping, flushing as well as varied starting level.

- Likewise, SPIDER has a built-in powerbank. So, there is no need for external battery backup in case of power failure

SPECIFICATIONS

Specifications for SPIDER Pump Control are the following:

| Dimensions | W=87mm x H=90mm x D=62mm |

| Weight | 250g |

| Wire connection | 0.5 – 2,5 mm2 |

| Vibration (sinusoidal) | 10-500Hz, 1G |

| Free fall drop | 30 cm |

| Enclosure class | IP20 |

| Power supply | 230V AC +10% / -20% |

| Frequency | 50/60Hz |

| Input power consumption | 0,004 to 0,06A |

| Starting current | <10A |

| Consumption | Max. 10W |

| Fuse | ≤250mAT |

| Certificates | CE |

| ENVIRONMENT | |

| Humidity | Humidity 10% – 95% non-condensing air |

| Operating temperature | -20°C to +50°C |

| Storage temperatur | -20°C to +60°C |

| Functional altitude | Max. 2000m above sea level |

| Start-up time total | 20-120 sec. (depending on GSM network) |

Input and output features for SPIDER Pump Control are the following:

| Built-in power supply | |

|---|---|

| Output voltage | 24V DC |

| Output current | Max. 100mA |

| Tolerance | +/- 20% |

| ANALOG INPUTS | |

| Number of analog mA inputs | 1 |

| Electrically insulated | No |

| Measuring range | 0/4–20mA |

| Input impedance | Approx.100 Ω |

| Measurement accuracy | Better than 0,5% of FS |

| Signal range | 0-24mA / 0–30V DC |

| Cable/signal length | Max. 100m |

| DIGITAL INPUTS | |

| Number of digital inputs | 6 |

| Electrically insulated | No |

| Digital signal | Low < 5V / < 1mA High > 12V / > 4mA |

| Analog signal measuring range | 0–10V DC |

| Analog signal impedance | Ca. 20KΩ |

| Measurement accuracy | Better than 1% of FS |

| Signal range (min/max.) | 0–30V DC |

| Cable/signal length | Max. 100m |

| DIGITAL OUTPUTS | |

| Number of digital outputs | 4 |

| Electrically insulated | Yes |

| Insulation voltage | 4 KV |

| Relay type | Relay outputs |

| Cable/signal length | Max. 100m |

| Relay NO #11 og #21 | |

| Constant load | max. 10 A @ 230Vac – AC1 max. 500 W @ 230Vac – AC3 max. 1 A @ 48 VDC max. 10 A @ 24 VDC |

| Minimum current | 5 mA @ 10 V |

| Maximum start-up current | 18A |

| Switch speed | Max. 1 Hz |

| Relay NO #31 og #41 | |

| Constant load | max. 2 A @ 230Vac – AC1 max. 100 W @ 230Vac – AC3 max. 1 A @ 30 |

| Minimum current | 5 mA @ 10 V |

| Maximum start-up current | 6A or 10A @ 20 ms |

| Switch speed | Max. 10 Hz |

ACOWA´s SPIDER has the following features:

- Advanced 1- and 2-pump control, where faulty pump is automatically taken out of operation.

- Built-in GSM / GPRS modem with “FAST RESPONSE” (available in two variants 2G or 4G)

- Multiprotocol, Modbus & Comli. SPIDER even detects what the SCADA system uses.

- 288 local logs per analog input, with freely defined time interval in seconds

- Status word with counter function for errors / alarms

- Connection of a graphical 2.4 ”OLED display, which is“ clicked ”directly on the SPIDER

- Connection of HMI 7 ”graphic color touch display, via serial HMI interface.

Functions:

- Emergency control function via level rocker if the pressure transmitter is faulty.

- Pump service indication, where SPIDER tells when the pump is to be serviced due to reduced capacity

- Function for overflow calculation with number, duration and quantity indication

- Function for daily exercise of pump so that it does not get stuck during prolonged downtime

- Function for daily depth pumping, so possibly. floating layers can be avoided

Connection to communication systems:

- Possibility of varied starting level, so that fat build-up is avoided

- Communication with frequency converter via Modbus (Danfoss FC202, Schneider Altivar Process and ABB)

- Communication with Siemens MAG6000 flow meter via Modbus

- Communication with energy measures via Modbus for KWh, Cosphi, Amp, Volt data for SCADA.

- Connection of SPIDER – I / O module, with even more inputs and outputs

- Configuration of SPIDER via Danish AcowaZoo PC software

NOTE! SPIDER is not EX-classified and therefore must not be installed in EX areas.

| Item number | Description |

|---|---|

| 1772-2100164 | SPIDER Universal ON / OFF controller with 2G modem |

| 1772-2104164 | SPIDER Universel ON/OFF controller with 4G modem |

| 1717-0B24-C884G | Quad band antenne (2G,3G,4G) w angle connecto |

The SPIDER Pump Control is very flexible and can be used in many different applications, such as:

- Control of Pumping stations

- Pump control at treatment plants

- Groundwater lowering

- Remote reading of data via ModBus

- Control of raw-water pumps